Contents

- What is IIoT?

- Why is IIoT important?

- 1. Real-Time Data Analytics:

- 2. Predictive Maintenance:

- 3. Enhanced Operational Efficiency:

- 4. Seamless Supply Chain Integration:

- 5. Improved Safety and Risk Management:

- 6. Quality Control and Productivity:

- 7. Energy Efficiency and Sustainability:

- 8. Remote Monitoring and Control:

- 9. Agile Decision-Making:

- 10. Scalability and Future-Proofing:

- Connecting the Facts about IIoT

- Secure Opportunities

- Your IIoT Journey

- IIoT Solutions

What is IIoT?

To put it simply; the Internet of Things or ‘IoT’ extends the capabilities of the internet to objects and devices, making them able to send, receive and gather data. In an industrial context (IIoT: Industrial IoT) the concept is the same; devices associated with manufacturing such as sensors, machines, and generators are networked together with internet applications for the purposes of control, management, and monitoring.

Why is IIoT important?

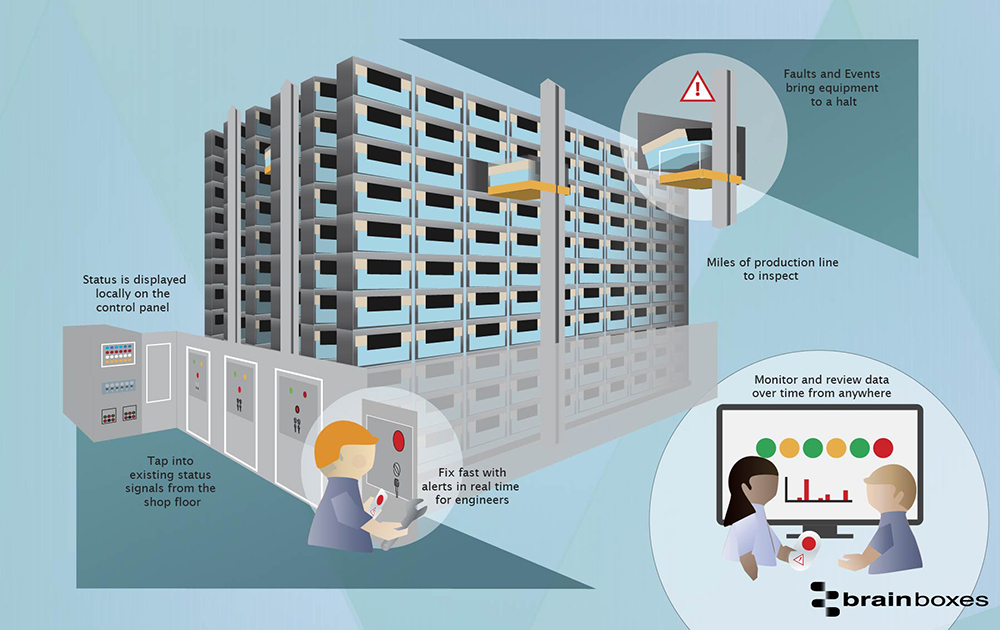

IIoT devices are able to collect data from their environment, react to this information, and make it accessible at greater speeds than ever before. Imagine a machine has a stoppage in one area of a large factory; with smart monitoring, a message can be automatically sent to a machine in another area to pick up the job and prevent a backlog while the initial stoppage is dealt with. IIoT devices allow more efficient monitoring and control which in turn generates cost savings.

IIoT empowers digital transformation, driving efficiency, innovation, and growth:

1. Real-Time Data Analytics:

IIoT enables the collection and analysis of real-time data, providing valuable insights into operations, performance, and customer behavior. By harnessing this data, businesses can make informed decisions, optimize processes, and uncover new opportunities.

2. Predictive Maintenance:

Gone are the days of reactive maintenance practices. IIoT sensors monitor equipment health, detect anomalies, and predict maintenance requirements. This proactive approach minimizes downtime, reduces costs, and extends the lifespan of critical assets.

3. Enhanced Operational Efficiency:

With IIoT, businesses can automate routine tasks, streamline workflows, and eliminate manual errors. By digitizing and optimizing processes, operational efficiency skyrockets, allowing businesses to do more with fewer resources.

4. Seamless Supply Chain Integration:

IIoT facilitates end-to-end visibility and traceability across the supply chain. From inventory management and logistics to demand forecasting and supplier collaboration, IIoT ensures seamless integration, minimizing delays and optimizing resources.

5. Improved Safety and Risk Management:

Safety is paramount in industrial settings, and IIoT plays a vital role in enhancing workplace safety. With real-time monitoring, predictive analytics, and automated safety systems, risks can be identified and mitigated swiftly, safeguarding employees and assets.

6. Quality Control and Productivity:

IIoT empowers precise and continuous monitoring of product quality throughout the production cycle. By leveraging data-driven insights, businesses can identify and address quality issues promptly, ensuring consistent product excellence and customer satisfaction.

7. Energy Efficiency and Sustainability:

IIoT enables smart energy management, monitoring energy consumption, and optimizing usage patterns. By identifying energy-saving opportunities, industries can reduce costs, minimize their carbon footprint, and contribute to a sustainable future.

8. Remote Monitoring and Control:

IIoT allows remote monitoring and control of industrial processes, equipment, and facilities. This capability enhances flexibility, reduces on-site visits, and empowers businesses to operate and manage their assets from anywhere in the world.

9. Agile Decision-Making:

With real-time data at their fingertips, decision-makers can respond swiftly to market changes, customer demands, and emerging trends. IIoT enables agile decision-making, enabling businesses to stay ahead of the competition and seize growth opportunities.

10. Scalability and Future-Proofing:

As industries evolve, scalability becomes essential. IIoT solutions are highly scalable, accommodating business growth and evolving requirements. By embracing IIoT, companies future-proof their operations, ready to adapt and thrive in a rapidly changing digital landscape.

Connecting the Facts about IIoT

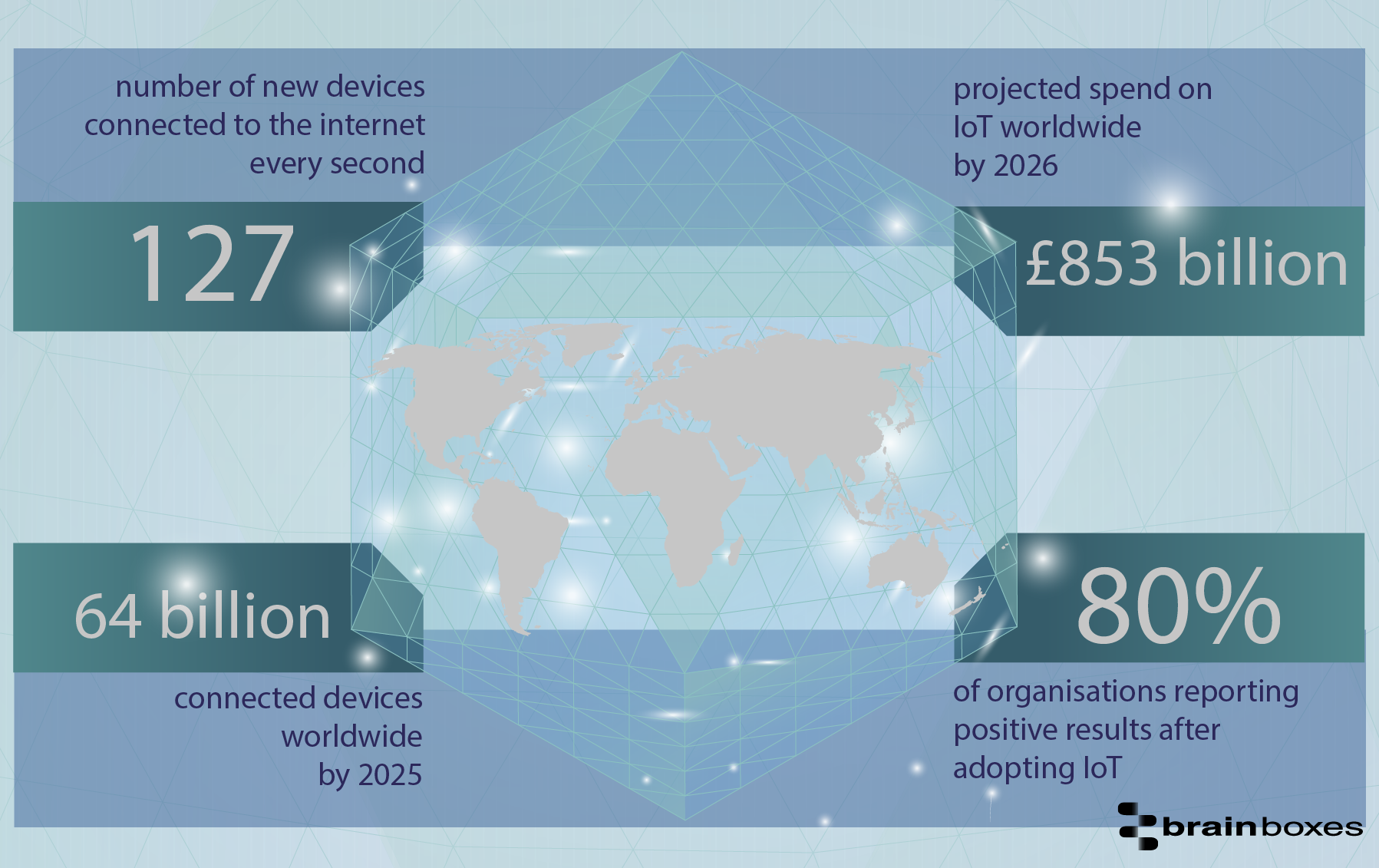

The IIoT is all about connections. Devices embedded with connectivity are able to communicate over the internet, allowing remote monitoring and control. Connecting objects to people, machines to other machines, businesses to the world: without connectivity, there would be no IIoT.

127 new devices are connected to the internet every second¹

In today’s Internet of Things; connected devices are no longer limited to things like phones and computers. Anything can be connected: toys, clothes, alarms, thermostats, production lines, the list is endless. If you can imagine it, it can be embedded with the technology to interact over the web.

The IoT devices market is expected to reach £853 billion (1.1 trillion USD) by 20262

A Fortune Business Insights report anticipates the IoT market reaching over 1 trillion USD by 2026. Valued at $190 billion in 2018, this puts the annual growth rate at 24.7%. The global IoT market grew to $250.72 billion in 2019 and is expected to grow to around $1.463.19 trillion by 2027.3

There will be more than 64 billion IoT devices by 20254

It can be difficult to visualise a number as huge as 64 billion. To use the analogy of time: 1 MILLION seconds = 11 ½ DAYS, whereas 1 BILLION seconds = over 31 YEARS. That’s a lot of devices connected to the internet.

80% of organisations report positive results after IoT adoption5

A Gartner study indicated that 80% of the organisations surveyed are seeing “better than expected” results after adopting IoT.

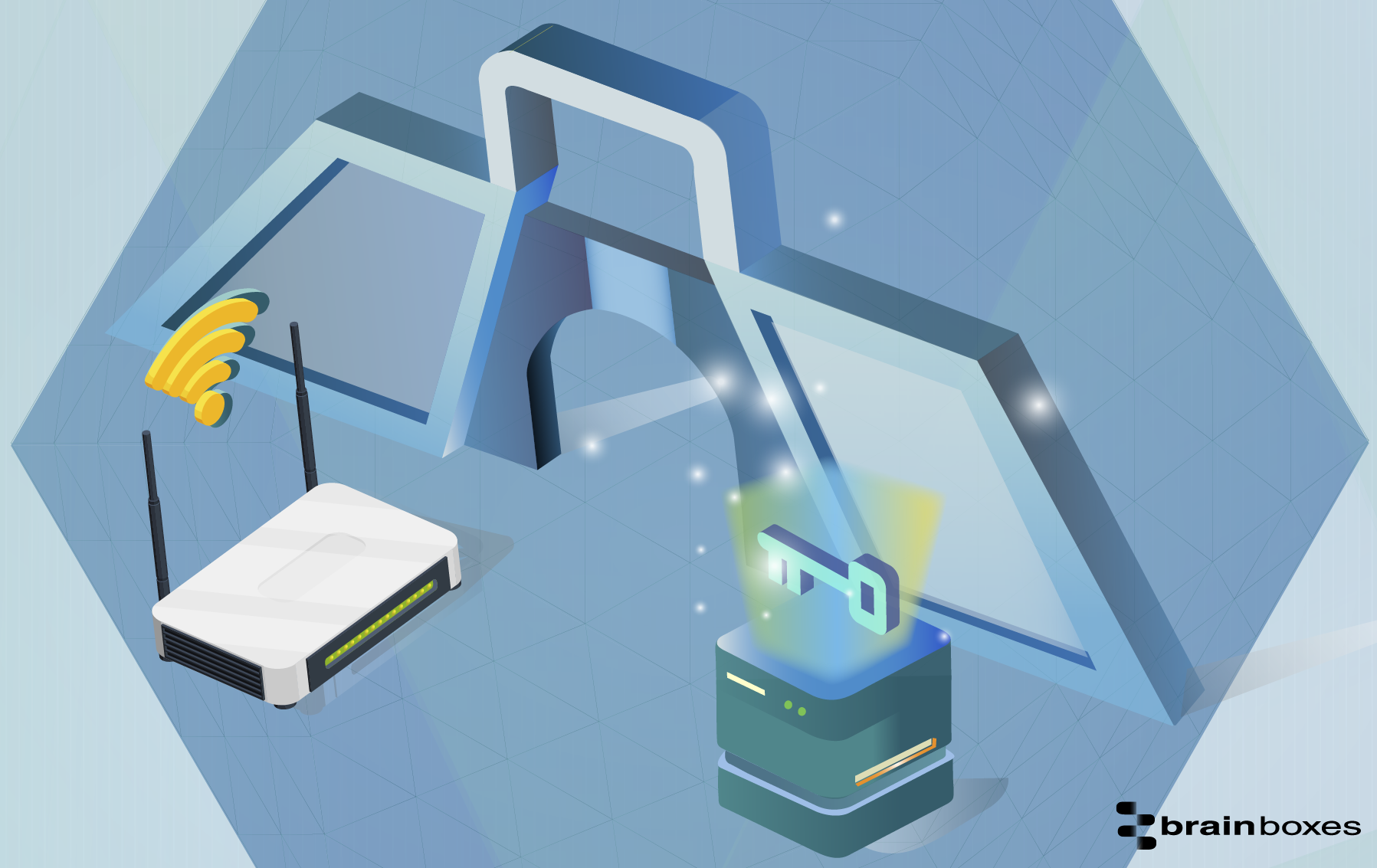

Secure Opportunities

More than 80% of senior executives see IoT as critical to their business6

IIoT brings a world of opportunities to industry. Networking machines, sensors and control systems together with industrial connectivity devices enables the optimisation of production lines, rapid response to demand, and efficient monitoring.

Increased productivity

Minimized downtime

Maximised margins

Decreased time to market

Increased quality

Your IIoT Journey

Integrating this new wave of connected technology can seem like a headache, and an expensive one at that. Whilst futuristic tech headlines are often drawn by huge conglomerates, it’s fortunately the reality that the smart sensors and powerful analytic tools available to the largest multinationals can be just as easily (and economically) dropped into the workflow of any small or medium sized enterprise. The tools and resources are often already there – they just need mobilising and utilising in new ways.

IIoT Solutions

In contrast to installing all-new machines; retrofitting existing setups and prototypes with smart solutions, particularly out-of-the-box devices, is the most effective way to disrupt the cost of implementing IIoT.

Raspberry Pi is a hugely popular platform in Internet of Things projects, and it’s easy to see why: it offers a complete server, in a tiny form, and all for a very low cost. The good news is that the traditional limitations of Pi in industry don’t have to be prohibitive to its use in IIoT applications. The BB-400 Industrial Edge Controller equips the compute module with hardware fit for purpose, an industrial Raspberry Pi eliminating the need to gamble with a system that doesn’t meet specs.

Discover Industrial Edge Controller

The ability to send real-time data across expansive spaces makes optimisation of any environment possible. In their vast warehouse in Nuneaton UK, RS Components have a system of 20 cranes at work over half a mile away from the monitoring panel. By installing remote I/O brainboxes to the panel, they were able to harness IIoT and send usable data concerning the cranes’ processes, productivity, and faults, to screens on the warehouse floor, supervisor’s offices, and onto a mobile app. Not only does this make vital information accessible to every team member, but analysis of the data allows RS to identify trends in productivity and adjust their processes accordingly.

Oxford University’s Global Jet Watch team has a network of 5 observatories around the globe. Ensuring one of their telescopes is in darkness at any given time is vital in collecting the right dark matter data for their research, hence the stations’ strategic distribution in longitude.

To collect data on the high-speed plasma jets that are squirted out of black holes, the Global Jet Watch team rely on IIoT-ready brainboxes, able to withstand harsh temperatures to reliably facilitate integration between the control panel in Oxford, UK and the observatories thousands of miles away.

As the Industrial Internet of Things is embraced by more sectors, it’s gradually becoming easier to visualise the 4th Industrial Revolution and what exactly it will look like. A far departure from WiFi-enabled floss dispensers and novelty-connected underwear, inexpensive IIoT solutions can provide immediate and measurable benefits to any size business right now.

3 Fortune Business Insights via Comparitech

6 GE